As a food company our future relies on the protection of the environment. Therefore sustainability has always been a key topic for us.

WE DID THE MATH: FROZEN FOOD IS ECO-FRIENDLY!

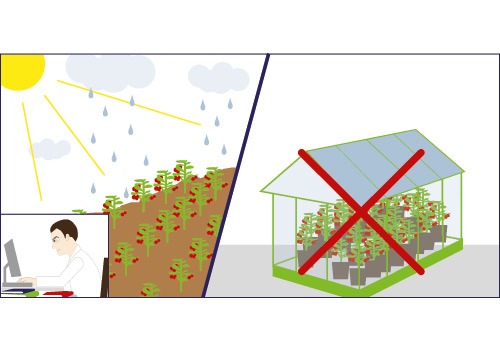

We have been dealing intensively with the topic of climate change and CO2 emissions. We calculate all of the emissions given out throughout the entire product life cycle.

We calculate the carbon footprint of all FRoSTA products. The result: Our freezing method and the Purity Command actually help to reduce CO2 emissions! This is also thanks to the huge FRoSTA kitchen, where we cook in a way that is much more energy e cient than at home.

By constructing a comprehensive Environmental Manage- ment system, we are now able to calculate the product carbon footprint (PCF) of a product at the touch of a but- ton, as early as during the development phase. That’s how we know that meals that contain meat or dairy products have a much higher PCF than vegan or vegetarian dishes. In recent years, the share of meat-free FRoSTA products has shown steady growth, and we want to increase it to 40% by 2020.

(in t CO2 e/t finished product; 2017/2013)

(in t CO2 e/t finished product; 2017/2013)

Since 2011, we have also been calculating our corporate climate balance. Here we calculate all emissions that occur within the boundaries of our 4 production plants. Here we can learn which areas can be improved even further, and can set specific goals for the future.

We were able to achieve significant reductions in CO2 emissions at all of our facilities over the last few years. There were several things that helped with this, for example refrigeration systems with heat recovery, biogas plants where plant waste is immediately recycled, and photovoltaic systems at our freezing facilities.

In terms of energy, electricity and gas consumption play an essential role. Our refrigerating and freezing processes together make up more than 20% of our total energy consumption Therefore we oblige ourselves to save energy and to reduce its consumption to the lowest amount possible. This starts with purchasing energy efficient raw materials, services and machinery. Through continuously optimizing existing machinery and facilities, energy consumption can be reduced and energy efficiency in turn be increased.

Each year we set ourselves targets in terms of energy consumption and our management provides resources and information necessary to reach these targets. This also supports our commitment to continuously improve.

Our energy policy applies to the entire FRoSTA company, including all our production facilities and supports our climate protection strategy, which is published every 2 years in a climate balance, which is part of our sustainability report.

Our FRoSTA company car policy also supports our energy-saving programm. We intruduced strict CO2 limits for all comapanies cars in 2012, which get lower every year. Everybody must comply with them – including the executive board. And: If an employee chooses a smaller vehicle model than his contract entitles him to, he receives a bonus! That’s why in 2014, 2015, and 2016, we were awarded with the Green Card by Deutsche Umwelthilfe for having an environmentally- friendly fleet strategy.

Environmental friendly packaging

Less packaging

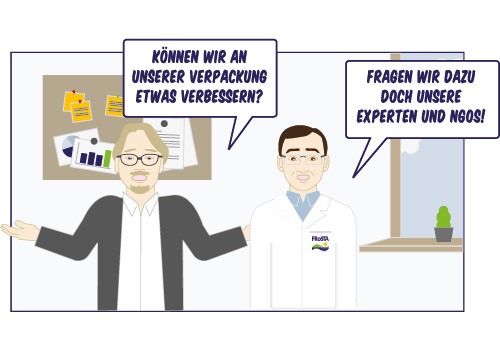

10 years after introducing our Purity Command, it was time to take a critical look at the packaging for our FRoSTA products.

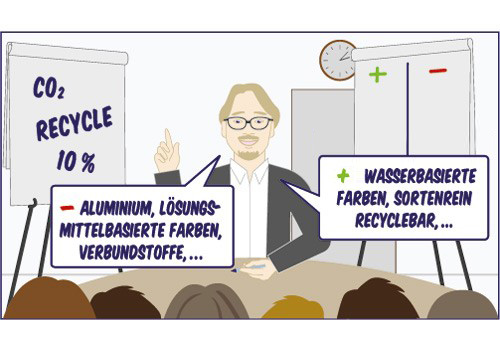

On the way to sustainable packaging, we rst checked where we could save on packaging materials. As such, we were able to reduce the materials used for outer packaging about a quarter, and therefore significantly reduced our CO2 emissions.

No aluminum

The materials themselves were also inspected. Because our goal was, and still is, to keep the impact of our packaging on humanity and the environment as small as possible. It quickly became clear to us that the use of aluminium – actually the standard packaging for most ready-to-cook fish fillets – should be avoided. Our FRoSTA “Schlemmerfilet” has been packaged in a PE-coated cardboard tray since then. Additionally, this also allows you to cook the fish fillet in 10 minutes in the microwave. That also reduces CO2 emissions compared to using the oven.

Water based ink and better recycling

In order to improve the recycling rate of our packaging even further, we developed bags made from polypro- pylene (PP). The new material for our bags and their new, light design means, that all FRoSTA packaging can now be recycled into mono-materials. The experts explained to us that you can only really make plant pots or park benches out of composite substances. From recycled mono-material packaging it is possible to also make smaller, more valuable plastic pieces. The recycled material can now be used in a lot more different ways. As we changed over to water-based printing inks, we were also able to reduce CO2 emis- sions from printing the packaging by up to 47%.

We worked very closely with our packaging suppliers and the “Grüne Punkt” on this project. Without the inten- sive exchange of ideas with them, we would have never been able to complete this project.

Transparency

FRoSTA stands for transparency: At our headquarters in Bremerhaven, we replaced a part of the wall facing the street with a glass panel. As such, anybody passing by can look in and see how we manufacture our prod- ucts, without having to make an appointment.

And we’re always happy to receive requests from journal- ists and camera teams who wish to report on how our products are manufactured. The public have shown great interest, which is why we always say yes to such requests. Just like direct communication with consum- ers, suppliers, and NGOs, these visits and interviews help us to understand how our company is seen by out- siders and what people expect from us.